Carl Moren History

The following article was written by Carl Moren and submitted to the collective history held at the Golden Museum. it was contributed in 2000. Carl died at age 94 in 2010.

My father Pete Moren at 18 years of age arrived at Boston from Sweden. This was 1905. He travelled by train to Wetaskiwin, Alberta where, for a short time he worked for acquaintances. He had served 7 years learning to be a blacksmith and carriage maker in Sweden. When he left, his mother asked him to that the name Moren as it had died out in a branch of her family. Their name, Peterson had become too numerous which presented some problems.

In search of work as a blacksmith he found it in a logging camo at Three Valley Gap west of Revelstoke, as an assistant blacksmith. He was educated by an Italian in the art of shoeing horses, making cant hooks, welding chains, etc, etc. He felt he was doing well mastering English swear words only to discover later it was mostly Italian goodies.

Over the next couple of years he helped his brother, Charlie and Victor, come to Three Valley. Victor was unhappy as dishwasher so they all went to Golden, where they were soon all working for the C.R.L. at Nicholson.

They met up with a big powerful Swede named Oscar Person, who was a very positive leader type. He changed all their lives. He had learned how to trap muskrats at Meeting Creek, Alberta which he had done until they were all gone. He convinced them all that they should go farther north, like the St. Paul area that had lots of lakes and sloughs and where there would be lots of ‘rats’ left. They could get $1.25 for each pelt and the C.R.L. was only paying them $1.00 a day.

Soon we see the 4 Swedes, Oscar, Pete, Charlie and Victor hiking on wagon tracks north of Vermillion with large packs heading for Stoney Lake. Interesting to not, none of them could ever carry all their worldly goods on their backs. Dad once told me that besides blankets, each had a single shot 22 rifle and a dozen Victor #1 traps and a hatchet. This was 1909, but they were not the first trappers after muskrats.

Their post office was Hopkins, where a ferry to cross the North Saskatchewan River has just been installed. There was a lot of good homestead land available for $10.00 per quarter, so they were all soon homesteaders. Dad married Oscars’ sister. Dad’s land had only 20 acres suitable for farming but if you expect to do all your farming with a team of oxen it may be pleny. Yes, Dad had a team of oxen to break up his 20 acres.

Dad’s first shack had a sod roof, mother said when it rained it continued for another 2 days to drain the sod. Dad built a new house of logs. I was born in the new house, plus 3 sisters and 1 brother. This was about the middle of the first World War. Uncle Victor had applied for citizenship papers which he soon got followed by army call up. He spent 2 years as a stretcher bearer before getting gassed with chlorine gas. He was permanently damaged so was unable to work at physically demanding jobs. He got no pension till well into W.W. II. In the settling of the family estate mother got a few hundred dollars and, mom and dad invested in a team of horses. Dad also heard of a new waterous sawmill the CPR was selling cheap at Vermillion. It had been in a train wreck. It had a lot of castings and a lot were broken. He bought it and hauled it home. He had to upgrade the sod roof shack to use as a blacksmith shop.

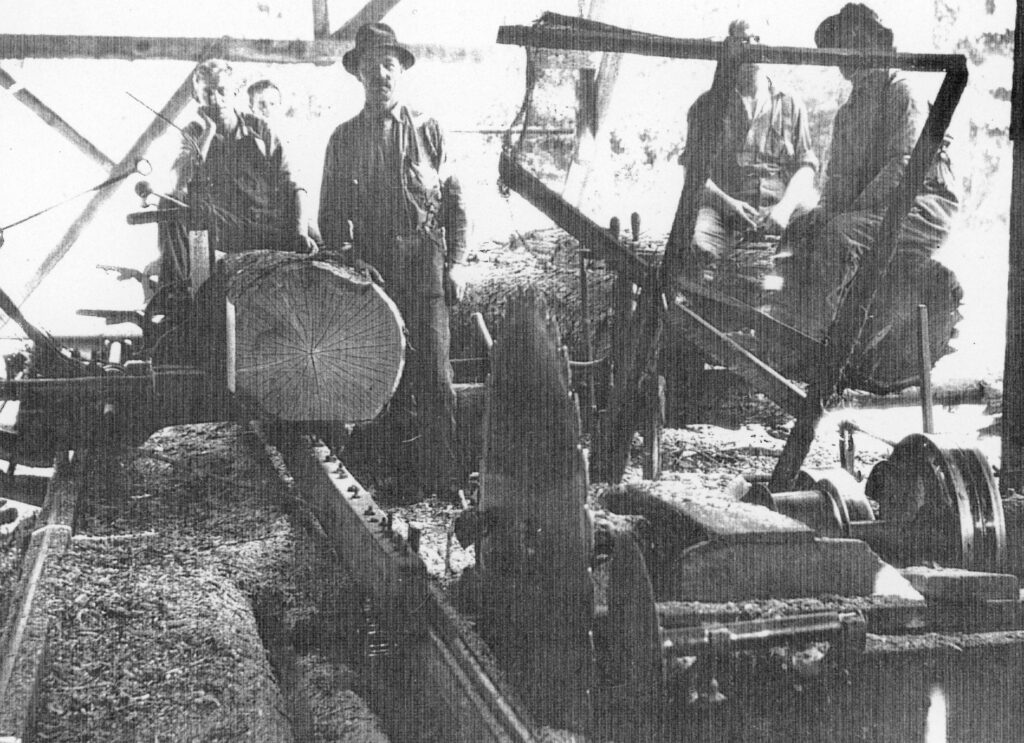

He purchased a post drill, bought drill bits, taps and dies. The broken castings were drilled, bolted, riveted and banded. Next he bought a portable steam engine of about 20 hp. It wasn’t a total disaster and he was able to prove he had a workable sawmill. He also learned enough steam engineering to get a 4th class certificate. This 20 hp engine was traded on a 20-60 Case traction engine and a well-worn 42” Case Threshing separator.

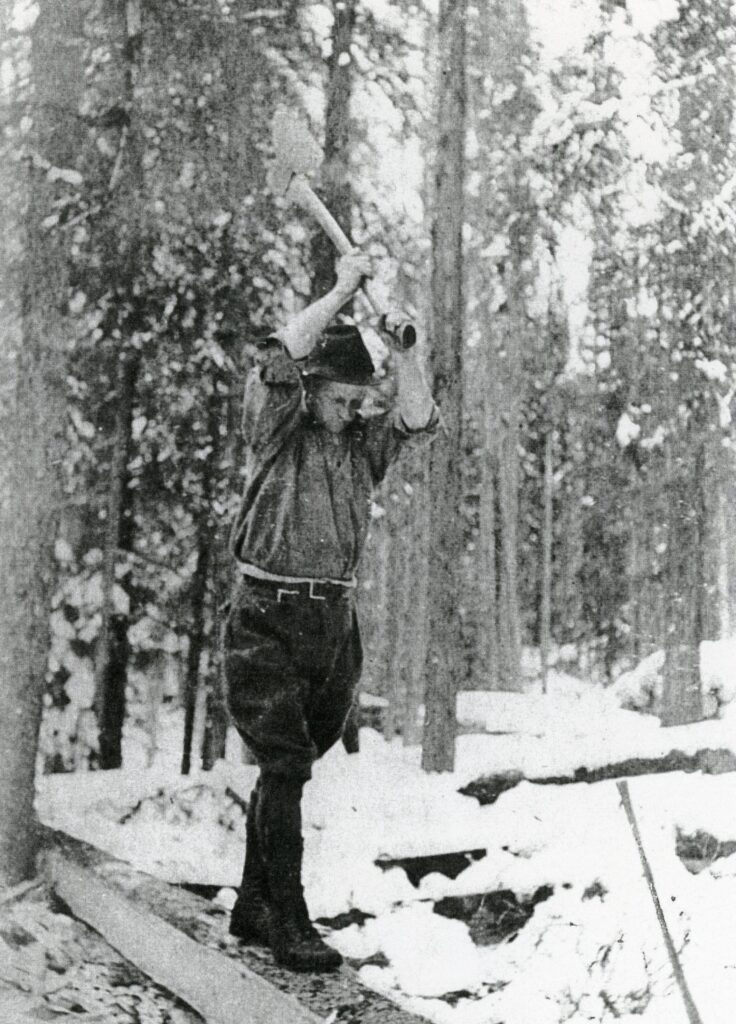

At this time, 1920, there was still some spruce suitable locally for saw logs but soon they became really scarce. About this time Dad’s youngest brother, Dave, came on the scene. So he saw big brother Pete, as a sawmill owner and operator. Uncle Charlie was away tie hacking close to Yahk, B.C. He was making money. Uncle Dave soon was a tie hacker too. Uncle Oscar was working as bucker in big timber on Vancouver Island. With 60 hp Case, Dad was sawing very well and was dreaming of timber, lots of timber. He figured CRL must have left some timber around McMurdo. He also realized the lumber would have to be shipped to Calgary. He contacted brothers Dave and Charlie with the idea. About this time Dad’s youngest sister arrived from Sweden. It was a good excuse for Uncles Dave and Charlie to come out to the homestead to see the baby sister, now 21. They saw the mill and some lumber. The three of them soon formed Moren Bros.

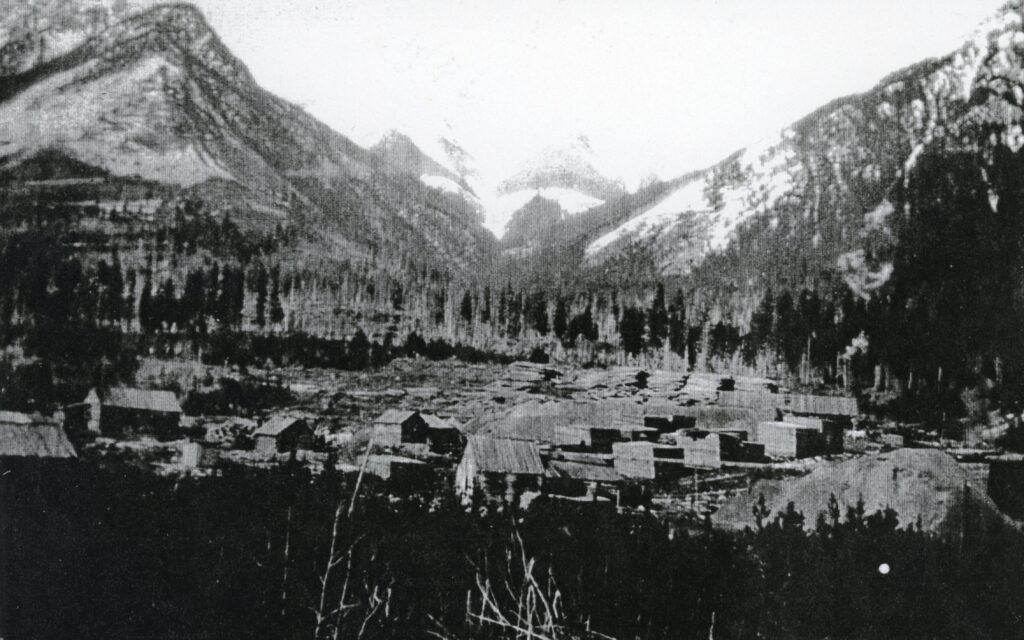

Through Ed Weston, Dad contacted Alf Braisher who would sell some timber. Dad made several trips to McMurdo by train and finally traded his homestead at Stoney Lake for all the Braisher’s timber.

Uncle Dave came out to help pack up which was a tough job. In one box car they shipped four horses and a milk cow, plus baled hay, oats, etc. The sawmill, shingle mill, and steam engine was shipped one year later. The animals were watered with pails when the locomotives took on water at water tanks.

Dad was fortunate at meeting Colby Jones, who lived next to the Braishers. He was going back to Oregon and allowed us to move into his house when we arrived. There was a barn and a hay shed with water. We finally arrived in McMurdo on St. Valentines Day, 1925, after a week on mixed trains. There was no loading platform at McMurdo. Dad and Uncle Dave borrowed some ties and used hay rakes to make a temporary platform. It was dark when we reached Braishers, and the snow was four feet deep. The next day we moved into the vacant Colby Jones place. I was nine years old, in a very strange world.

A piece of land for the mill-site was rented from Billy Smith, a great old guy. The land was small and up against the McMurdo School yard so couldn’t very well be expanded.

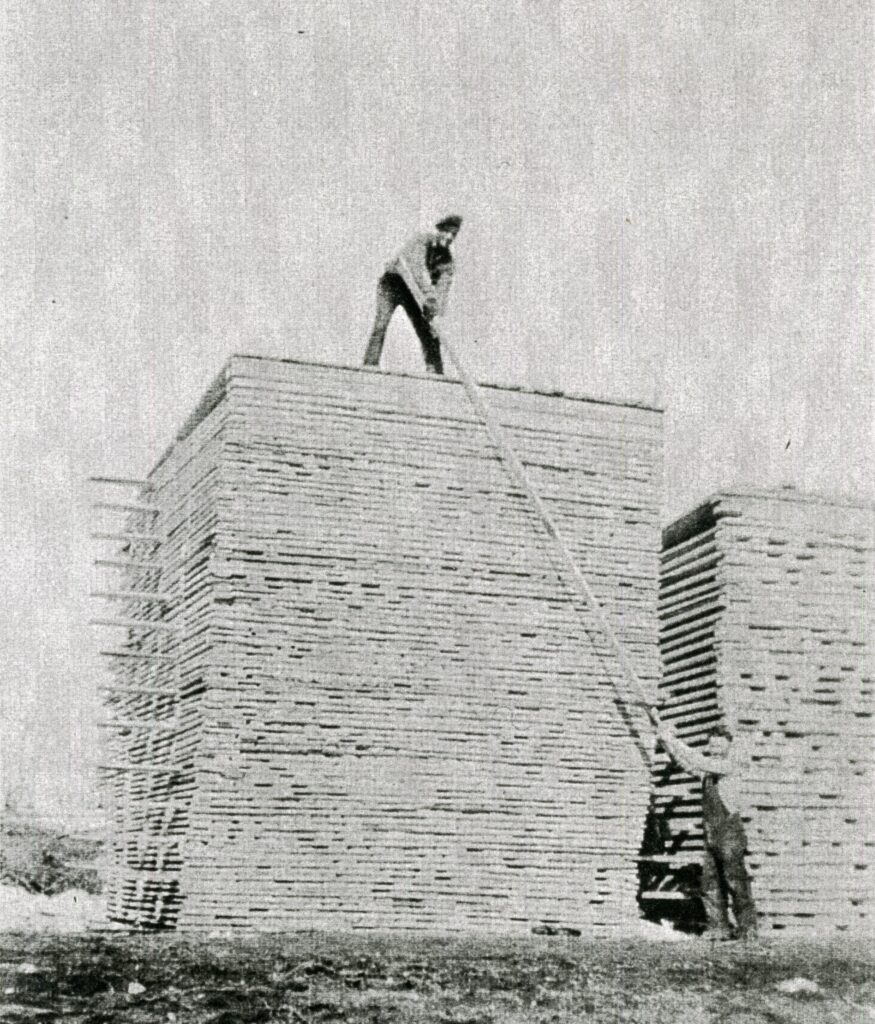

Uncle Charlie kept on tie hacking locally while Uncle Dave also made some. Dad went back to Alberta threshing. Short of money? You bet! Finally the mill machinery arrived and Dad surprised our close neighbors by actually producing lumber. The American Able engine he shipped in didn’t have the power of the Case engine left in Alberta for threshing. He also had to buy a new blade and drive belt, then through a contract technicality he had to give Braishers back the timber. Moren Bros was badly wounded, but not dead. Mother was camp cook. Sister Ruth and I went to school. She also had 3 preschoolers, 2 sister ands and my brother to care for. With a planer purchased from Tom Alton, Moren Bros shipped four carloads of lumber to Crown Lumber in Calgary in 1928, from a small timber limit.

Moren Bros built a camp close to the sawmill and school. My teacher was Freda Forslund, she was a very strict but a great teacher. Moren Bros had hired Bob Smith and Woody Jacobs who told Dad about a nice patch of timber up on the bench at 12 mile between Harley Jacobs and the mountain. Moren Bros soon viewed it, and bought it, so we had to move again. Mother was much concerned as there was no school. With some effort a school district of Mountain Ridge was formed. The school was built entirely by volunteer labor. A neighbor, Sargent, with two daughters, was the head carpenter. I personally donated three weeks of my time firing the steam tractor engine to log, saw and plane lumber for the school. Harley Jacobs donated the timber which he and Woody felled and cut into log lengths.

Moren Bros had a contract to supply timbers for the Parson bridge so some extra logs were cut. So we did some summer logging with sleighs on bare ground pulled by a steam tractor. Next summer Harley Jacobs, Woody Jacobs, Ben Fisher and I shingled the school roof. We had Dorothy Dewar of Vancouver as a teacher for three terms. I appreciated her a teacher. Hedley Dartt of Golden had financed A. Bentley, a sawmill man of Canal Flats area who went broke. Dartt also had a 100 hp case skid mount engine on his hands. Worse yet boiler was condemned for a bad job done on expanding leaky flues. Dartt sold it for $900 and dad knew he would have to replace all the flues and also get some boiler makers tools. He got the tools, and reflued the boiler sufficiently to satisfy the boiler branch. In later years I have wished I had paid attention to how he coped with the problem. Moren Bros. now finally had sufficient mill power. They used 5 horses in logging and 7 men. We had one skid horse who we valued highly for his obedience and intelligence. The log hauling on the bench was easy compared to the McMurdo school log road which was so steep it was dangerous. Moren Bros settled in for a five year run and actually made a bit of money in the dirty thirties. Lumber delivered to Calgary netted them from $21.50 to $23.00 per board foot. Much of it went to Crown Lumber Yards around Calgary.

Dad soom learned the hard way that circular saws need to be hammered on occasion. He couldn’t do that. A Mike Hansen of Athalmere hammered ours a few times, and then needed a loan of $75.00 to bale out some truck parts and because Dad helped him out Hansen told dad “Get yourself a proper anvil and straight edge cheap. Three years later when dad had given up hope, Mike Hanson pulled into camp. Dad got two days of hands-on instructions. When we were sawing spruce at -35 degrees north of Cold Lake, dad remarked several times that the loan of $75.00 was one of his better investments.

In 1932, Moren Bros had logged out their timber so would have to buy more, likely across the river to the west. Mother wanted to go back to farming in Alberta. Uncles Dave and Charlie were not enthusiastic about settling up the mill again. My vote didn’t count but I would have stayed. Dad bought 2 quarters of raw land at lowered prices. Uncles also bought an existing farm. We traveled by car and truck shipping a couple car loads of lumber and supplies. We arrived in the Elk Point area on Halloweeen night. It’s a great time to start building a house or hand dig a well in Alberta. Fortunately we had three weeks of reasonably good weather. Dad had to go back to McMurdo to get the 100 hp steam engine and mill machinery loaded and shipped. He had taken over this when Moren Bros. dissolved partnership. Our first setting three miles east of Muriel Lake was a tough learning experience. We sawed lumber on half shares so money wasn’t visible until later. I had been the steam engineer firing with planer shavings in BC for 6 seasons. I had much to learn about frozen pipes, hoses and water tank. I finally got dad convinced we had to have a shack around the boiler. This solved several problems. Our saw blade perfect in summer had too few teeth for frozen logs that were almost metallic in hardness. A couple of winters later a new blade solved the lost tooth problem. We moved our operation to north of Cold Lake to better timber. Dad traded the waterous mill for a bigger oxford mill. We also started running a night shift. First with a couple of gas lanterns and later we got a 32-volt generator and 32 volt bulbs.

Now during the summer, we farmed with horses for enjoyment. About July 1st we rushed to Cold Lake to plane lumber and send it to local lumber yards. Then suddenly we had to go threshing. I mastered the fine art of firing the 20-60 Case with straw. Now that was a steady job. According to our boiler inspector I may be the last man in Alberta who fired a steam engine with straw.

Dad purchased a rubber-tired Model D John Deere tractor which soon cut out the horse problem and we threshed with it too.

Meanwhile, mother died in 1938. We had a bigger and better house built by then. Sister Ruth went to Art School in Calgary where she married, raised a family of 4 boys and 1 girl. Ruth died of Parkinson’s disease in 1999. She stayed in Calgary where she set up and operated Barnes Art Supply. Sisters Ellen and Gladys both became high school teachers. Eventually Ellen married a stock broker who worked for C.F. Hutton’s; she lives in Chicago and is now Mrs. Dore. Gladys married a university student whose expertise is numerous. As a metallurgist and electrical engineer he specializes in big electrical furnaces and is a very successful inventor. They live in Florida and are the Earl Stanleys. Brother Clarence showed genius in a number of ways. I was building some short wave radios as a hobby. He wanted to know how it all worked. He was five years younger but he could keep right up to my technical advances. I had a collection of about 25 pocket watches. These were of the chap sort. I had made small screw drivers from bicycle spokes. I could see I would never have time to spend on this so I gave the works to Clarence and in a short time he had many cleaned and working. He also did one smart thing. He bought a book on clock and watch repair. He soon had gathered real jewelers’ tools and fixed a lot of watches and clocks. He went to SAIT in Calgary and took a one year course in electricity and another in radio. He paid for this by fixing watches. World War II was in progress so he joined the airforce. He got sent on course after course, the airforce was developing another instructor. He found this out when he left them, he only got a conditional discharge.

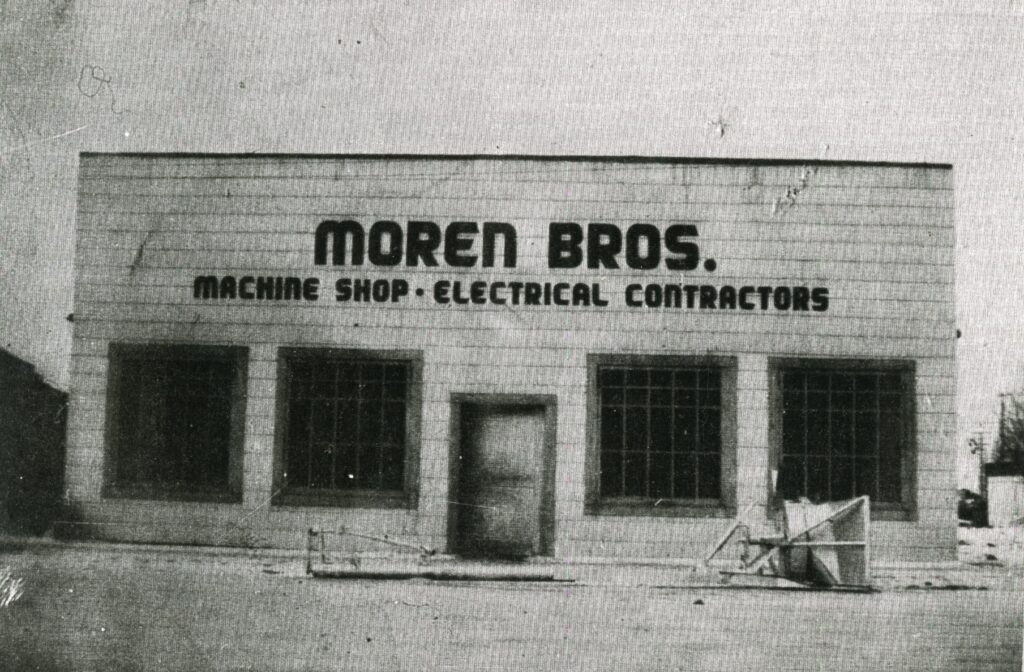

Dad remarried. I went to work for the St. Paul Foundry at St. Paul, Alta. I signed up as apprentice welder and machinist. The next 2 years were the most intensive learning period of my life. I worked for $40.00 per month and paid $25.oo for room and board. After 4 months my pay was raised to $80.00 per month. My boss was the best oxy-acetylene welder I ever met and a true genius in many other ways. A couple of friends went ship building on the coast and were getting sixty cents per hour as labour – fantastic. I wrote to a former neighbor in Victoria working on a shipyard getting 90 cents per hour as carpenter. I left St. Paul Foundry with some regrets to go ship building. I found work with the Pacific Sheet Metal Co, who had contracts with both shipyards and was soon installing bulkheads. I started at sixty-five cents an hour. I held a key position because I could cut with a torch, weld and especially read blue prints thanks to popular mechanics magazines. The manager also got my liquor permit each month. The draft board was soon after me but the company managed to get me deferments. I didn’t escape the military completely because I had to join the reserve army. This wasted most of my spare time. In 1945, after 4 years and work on 17 frigates, 6 transport ferries and 2 liberty ships I went back to Alberta to make my million my way. Dad had sold his mill compete at Cold Lake but had a home-made mill that worked. Timber does grow back. So Clarence and I used dad’s equipment on the farm and produced lumber to build a 40 X 60-foot machine shop in Vermillion which we did do ourselves. A lathe and milling machines were purchased from the CPR. We opened the door for business in the winter of 1947. Clarence stayed with the electrical and after about 5 years together we split so that Clarence could go more into sales. He had mastered refrigeration by then. I stayed on for 20 years, had 4 small kids and a runaway wife, taxes doubled. I sold out, piece by piece. Clarence did well as Moren Electric – sadly he was killed by a drunk driver in a 1981 accident.

I went millwrighting in B.C. for 3 years, one year of ship building in Australia and then back to work as steam engineer for Suncor. As chief I never had it so good Now retired, I kept lots of tools for some hobby stuff. The Uncles, Charlie, Dave and Dad retired in Vernon, where they lived until they all died. Charlie’s wife and my stepmother died the same day. Dave’s wife, Hazel, still lives in Vernon.